Dincel Installation at CIVENEX

Published 12 March 2019

Aside from learning how Dincel Structural Walling can be used as an alternative to traditional concrete formwork in their next civil project, Dincel will be using the CIVENEX expo to introduce the newly developed Dincel 275mm Reinforced Earth Retaining Wall option with various finished including sandstone flagging, Astec texture paint.

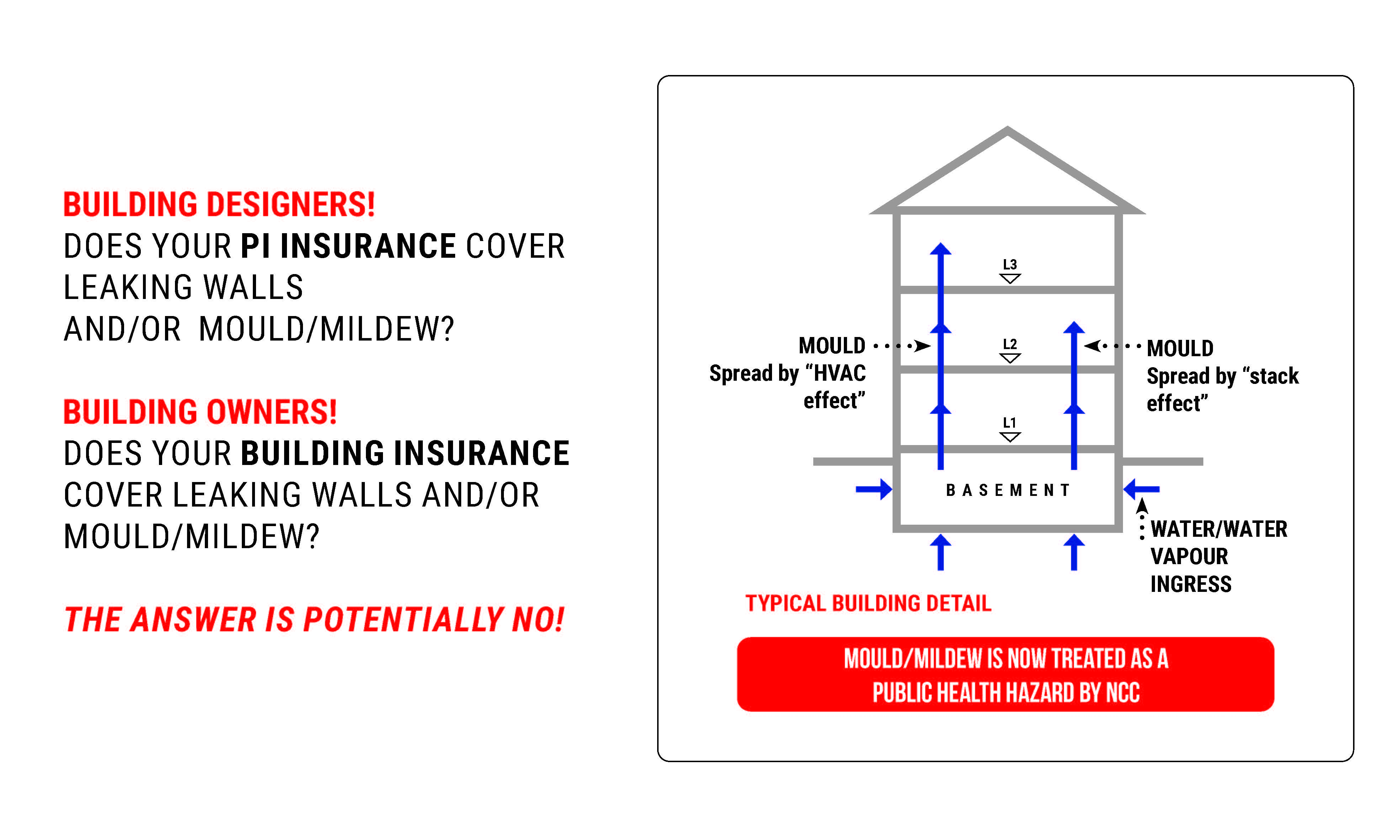

Waterproof warranty

Should they choose Dincel Installation to manage their basement or tank design, supply and installation, the company will provide them with an industry leading waterproof warranty.

Unique within the industry, this offer applies to all such projects involving the Dincel 275mm profile, which is particularly attractive to the civil structural market.

One of the key benefits of this sustainable building material is that, unlike other methods, it dramatically reduces waterproofing membrane requirements and completely eliminates the need for wet trades.

This is because the panel joints and surface are completely waterproof. Therefore, there is no need to apply a waterproofing membrane on the vertical wall joints or surfaces. The only place that does require waterproofing is the horizontal cold joint at the supporting footing/ slab & wall junction.

This feature has been tested under 6 m of water head pressure and the product is certified as waterproof by CSIRO Australia.

Strong, fast and less expensive

With representatives from Dincel Installation on hand at CIVENEX to answer questions as they arise, visitors to the stand will also be able learn about the various other benefits of Dincel, as compared to traditional methods like in situ or precast concreting.

While these conventional methods are reliable, they are also complicated and time-consuming. In situ concreting, for example, requires a lot of manpower, infrastructure such as cranage, and timber formwork.

An easier way to install waterproof and reinforced concrete walls, Dincel cuts construction time by up to 50 per cent. It reduces labour hours, and typically less reinforcing than traditional methods and eliminates the need for things like cranage and timber / site storage during conventional formwork stripping phase.

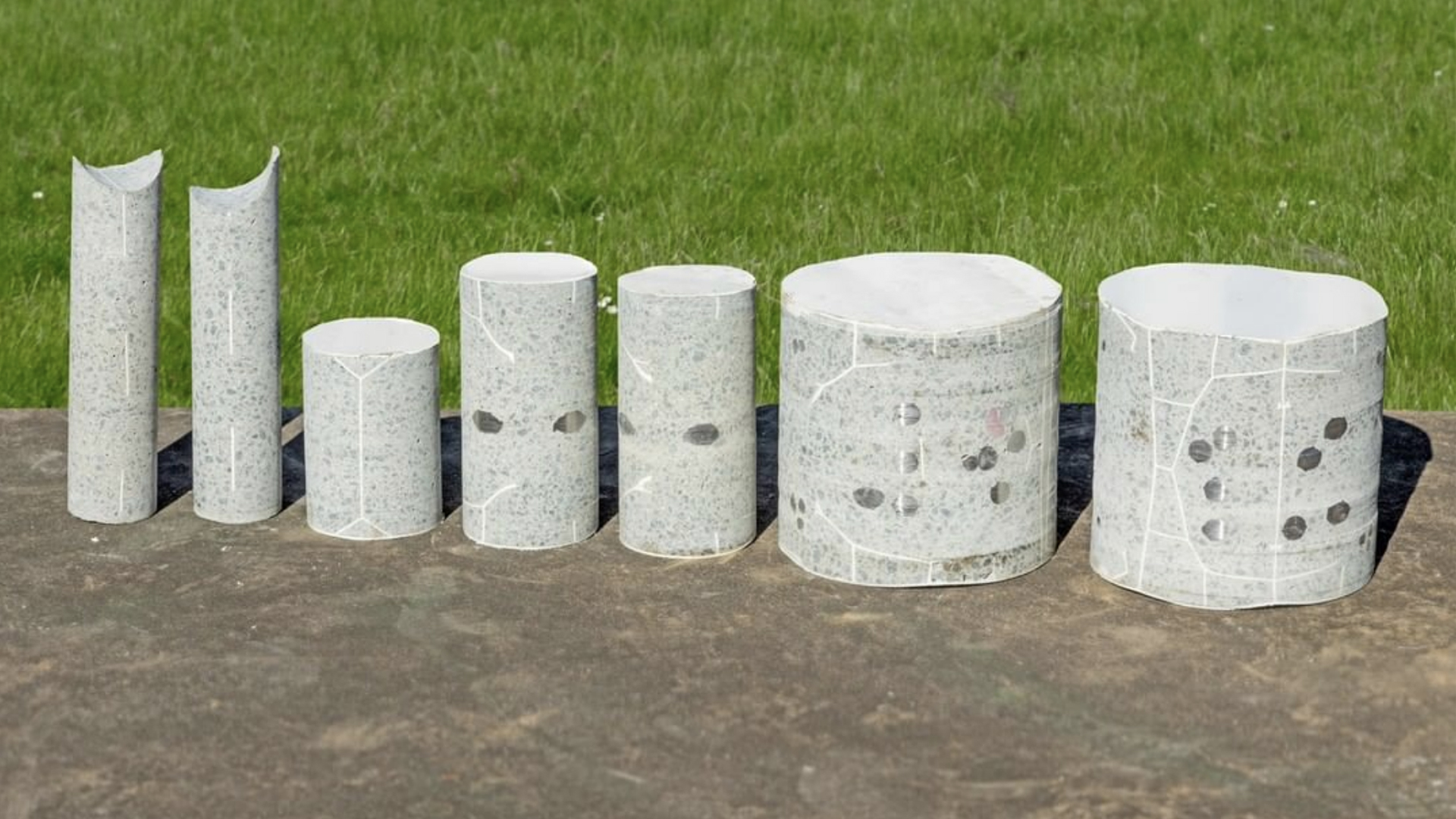

The key difference between Dincel and traditional techniques is that, using the Dincel system, the concrete core of the structural wall is encapsulated within a protective polymer skin.

Connected via a unique patented snap-lock joint system, the Dincel panels don’t only simplify the technique. Importantly, when incorporated with steel reinforcement & readymix concrete , they form solid walls suitable for load bearing structures across all types of industries, from OSD tanks & culverts to high-rise construction.

Because it eliminates the need for cranes and reduces the amount of materials and labour on site, Dincel also has positive safety implications. All these factors translate to less ways for people to get hurt.

On top of that, reduced waterproofing requirements means that there is less need to work in confined spaces, such as between the retaining wall and excavated soil. Because there is no need to work in these spaces, the size of the excavation can be reduced. And the strength of Dincel means that soil backfilling is possible just 24 hours after the concrete pour.

Versatile

Versatility is a further benefit of Dincel. From an aesthetic perspective it is suitable for use with several types of exterior wall cladding including stone or timber. Or, if preferred, it may also be painted.

Available in a range of profiles, widths and with various other components, it is a sustainable building material for almost any project. It can be used to create curved walls for things like water (detention, retention or stormwater) pits, waste water tanks or petrol tanks.

Lightweight and easy to handle, one person can safely carry and install Dincel panels on congested sites. With the assistance of Dincel Installation’s engineering team, there’s virtually no limit to the design requirements it can handle.

Co-located with the Sydney Build Expo, CIVENEX covers all sectors of the construction industry. Featuring more than 200 exhibitors, the event provides a unique opportunity to not only catch up with the latest equipment, sustainable building materials and services, but also to take advantage of networking opportunities with key industry players.

Visitors to CIVENEX can find Dincel Installation at Stand C57.