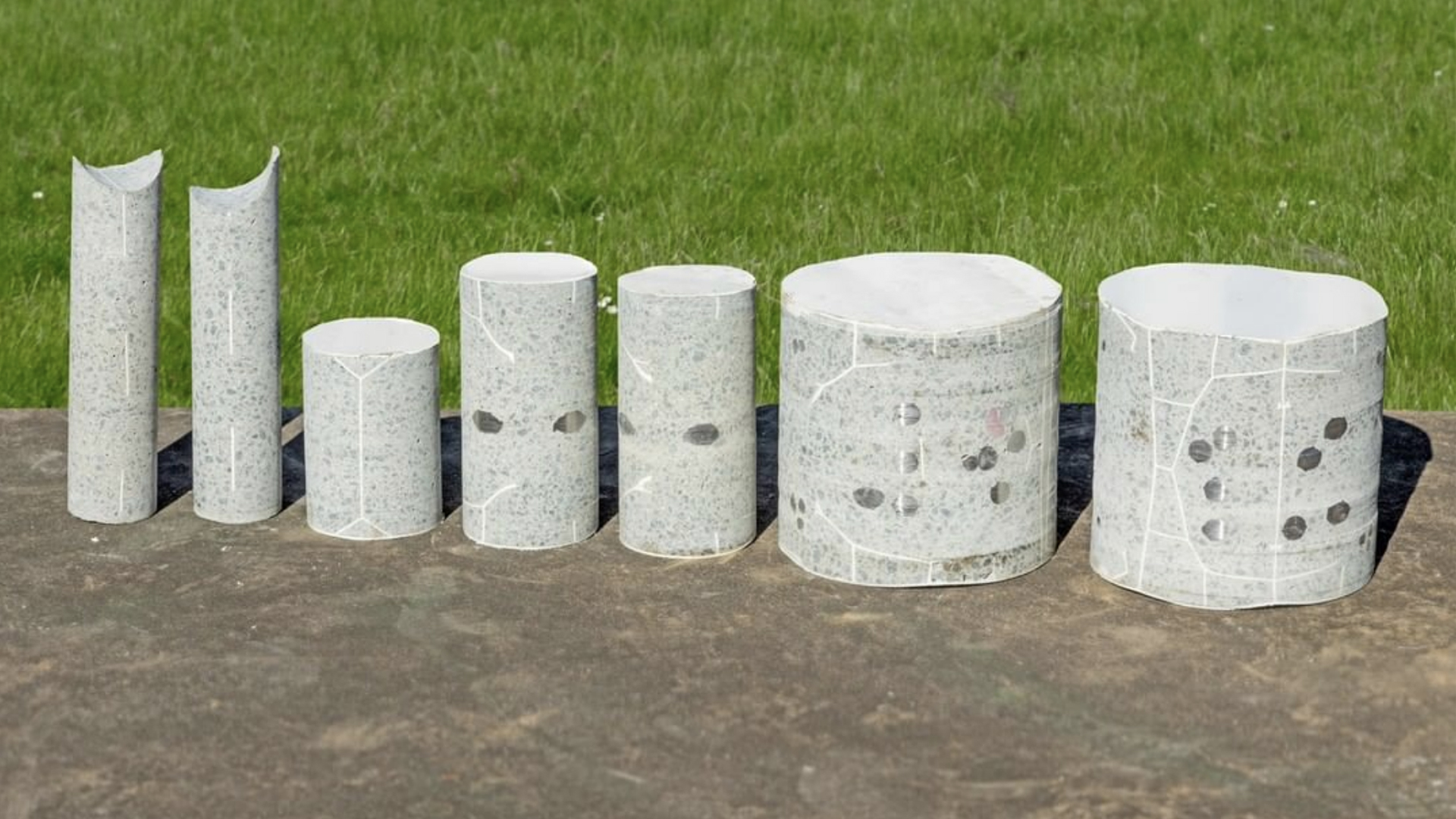

Dincel 275 Profile Strength Tested at UTS

Published 14 August 2020 | Download PDF Version

The Dincel 275 profile, which contains a unique cylindrical formwork shell, has undergone strength testing at the University of Technology Sydney (UTS).

UTS has confirmed that 275 Dincel can be designed and installed without the use of steel reinforcement bars, consisting of the following concrete infill:

Mass concrete, or

Macro synthetic fibre (BarChip) reinforced concrete

The testing was completed in accordance with the requirements of AS 3600-2018 (Appendix B) and is certified by UTS as compliant with the National Construction Code 'deemed-to-satisfy' provisions for structural requirements.

In addition, the loading was applied onto Dincel 275 walls containing either early-age concrete (after 24 hours) or later-age concrete (after 28 days). Results demonstrate that Dincel 275 walls can be backfilled 24 hours following concrete infill (with appropriate bracing), which allows for construction of the superstructure to take place earlier.

Industry First Innovation

By omitting steel reinforcement bars, Dincel 275 is able to offer the following benefits:

Faster, safer and less excavation resulting in incredibly cost-effective installation.

Significant reduction in embodied energy and carbon footprint. (Reduced steel manufacturing)

Exceptional concrete compaction, as the omission of horizontal steel reinforcement bars in particular enables unimpeded concrete flow. When coupled with 275 Dincel's unique ability to handle up to 300mm slump concrete, air-voids are not possible. Air-void free concrete in Dincel 275 ensures an increased asset life by preventing potential corrosion issues and eliminates the need for wall waterproofing.