Avoiding Concrete Segregation In Walls Leading To Cold Joint Problems At Wall To Slab/Footing Junctions

Published 12 October 2022

The Unresolved Problem.

Water leakage at the cold joint between a wall and slab/footing due to unavoidable segregation.

The Reasons Why

Over the past 12 months the Dincel Group has conducted extensive AS3735 waterproofness tests with excellent results. Learnings from this testing have revealed that irrespective of using self-compacting concrete (SCC) or conventional concrete in permanent formwork systems*, besser blocks or conventional steel/plywood formwork, segregation is largely unavoidable under any circumstance.

With conventional formwork use, segregation is usually associated with the free fall of aggregates from height. In the case of permanent polymer formwork systems, the internal webs have perforations that work like an elephant’s trunk which stops the free fall of aggregates and as such eliminates segregation.

Observations by Dincel have, however, revealed that there is another reason for concrete segregation - the concrete sitting within the pump hose before the commencement of concrete pouring.

The concrete waiting within the pump hose loses cement paste, leaving greater accumulation of coarse aggregate. The longer the wait time to start concrete placement the worse the segregation of aggregate from the cement paste.

Practically, it is not possible to disperse and mix the already segregated concrete at the bottom of the wall - even with good vibration practices. The reality is that even expert vibration practices will only begin at least after the placement of a few hundred millimetres of concrete depth.

The Solution.

The only way to avoid this problem is to discharge the already segregated concrete before beginning with the placement of concrete. It need only be a minimal amount that is discharged to waste, but this will ensure a cohesive wall to slab/footing junction.

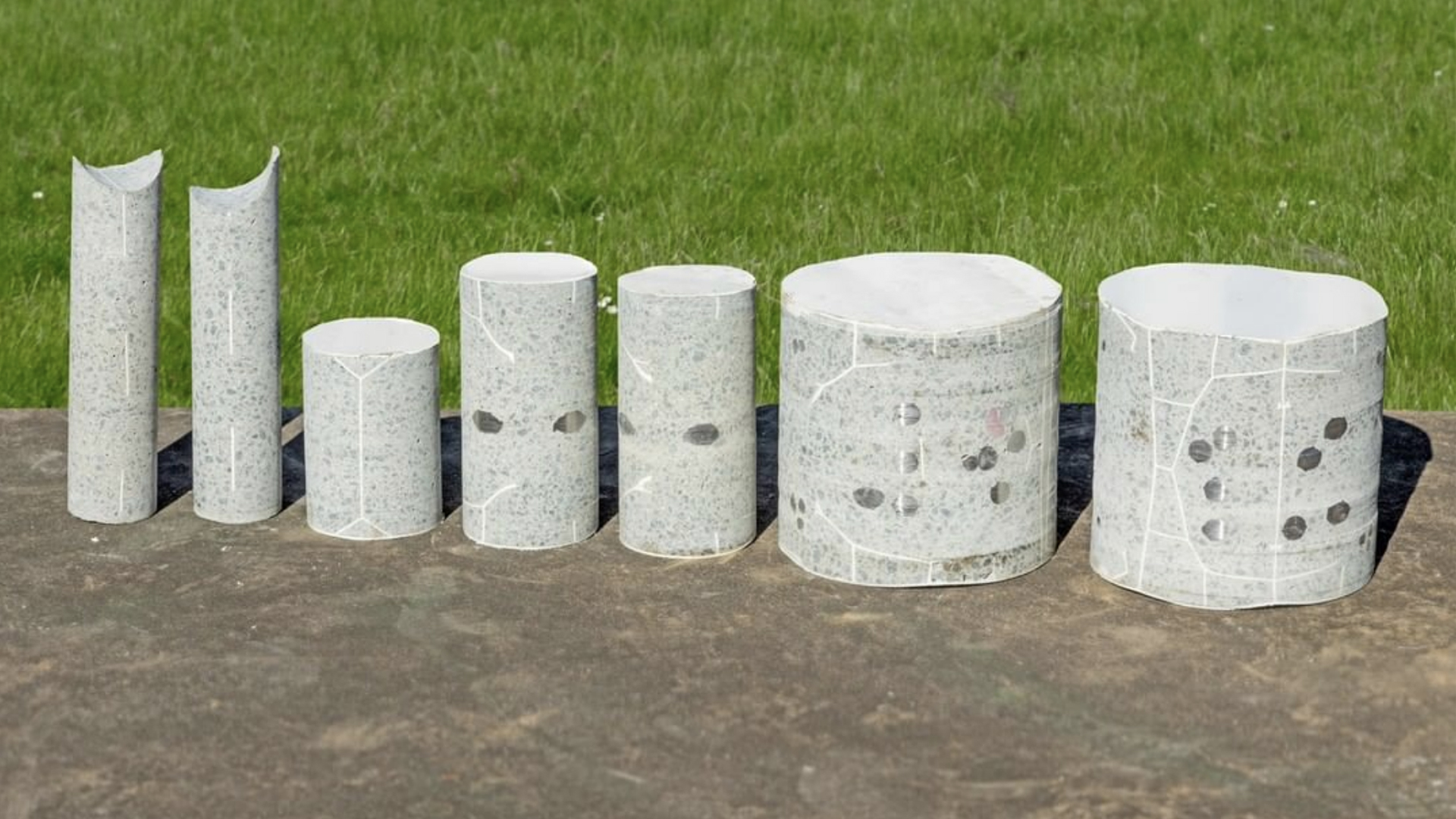

| The concrete waiting within the pump hose at the kink created by the hose clamp loses cement paste, leaving greater accumulation of coarse aggregate. |

| Prior to starting concrete placement, discharge the segregated concrete. |

| Concrete that was sitting within the pump hose discharged into a barrel prior to the commencement of the concrete pour. |

* polymer, fibre-cement, double-precast wall